for biomass pyrolysis

for biomass pyrolysis

for biomass pyrolysis

for biomass pyrolysis

Type of Action

Horizon Research & Innovation Action

Budget

Partners

Countries

Term

July 2023 –

June 2027

Project Video – get to know the process in 1 minute (and 10 seconds)

PYSOLO – Making use of concentrated solar power for biomass pyrolysis: new paths for a climate-neutral Europe

The EU chemical industry urgently needs to abstain from fossil resources and to move towards the use of renewable carbon. Energy and heat needed for industrial processes can be derived from renewable sources such as solar energy. However, this decarbonisation through electrification of the industry is not sufficient to meet the goals of the Paris Climate Agreement. In parallel, the chemical industry needs to be defossilised. For this, the raw material for chemicals and materials must come from renewable sources, e.g. biomass.

PYSOLO (PYrolysis of biomass by concentrated SOLar pOwer) offers a solution for both decarbonisation and defossilisation by preparing the ground for a fully renewable process combining concentrated solar power and biomass pyrolysis. Thanks to the use of solar heat in the pyrolysis process, the production of valuable products bio-oil, biochar and pyrogas can be maximised and the associated CO₂ emission minimised. This offers both economic and environmental benefits compared to conventional pyrolysis.

Making use of the heat of the sun

Concentrated Solar Power (CSP) is a technology in which sunlight is captured by several movable mirrors (heliostats) and directed onto a solar receiver. The selected receiver technology is a rotary kiln particle receiver, in which solar radiation is concentrated to heat up a solid particle hear carrier (PHC). The particle receiver is being further developed and refined within the PYSOLO project in order to use the heat produced for downstream heat-intensive biomass pyrolysis.

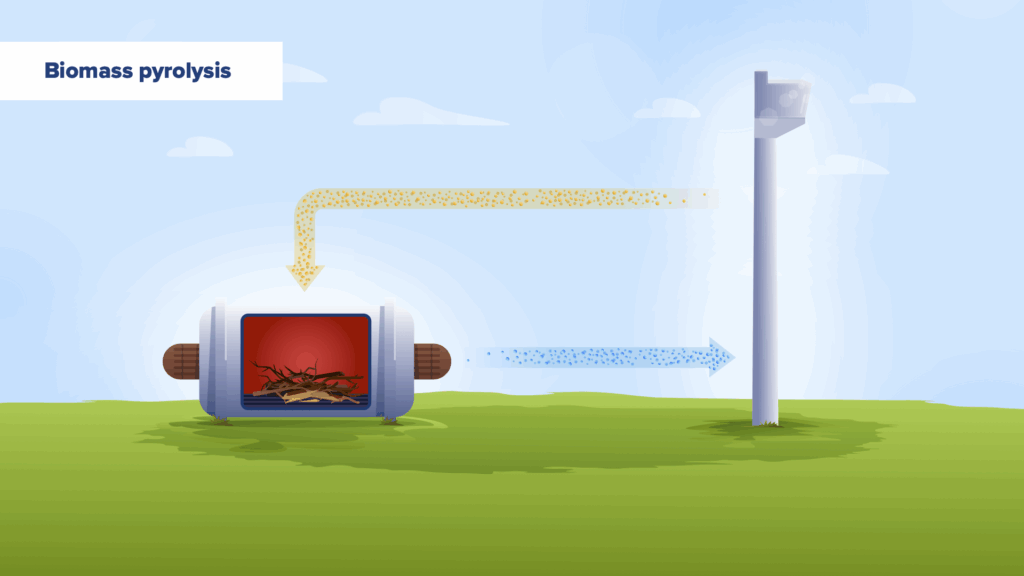

Converting biomass into alternative energy sources

Biomass pyrolysis is an endothermic thermochemical process that enables the conversion of wood into high-value products such as bio-oil, biochar and pyrolysis gas with high conversion yields. These renewable products can be used for both energy and non-energy applications, e.g. as biofuels for the transport sector and as biochar for agricultural purposes (for soil amendment).

In conventional pyrolysis, the required heat is generated by burning char and pyrogas. As char and pyrogas are also high-value pyrolysis product, their combustion is an economically and ecologically inefficient step which also results in additional CO₂ emissions. Generating heat through CSP instead of burning a fraction of the pyrolysis products is therefore a logical and sensible step.

Full flexibility for self-mode and balancing of the electric grid.

Nevertheless, the combustion of pyrogas and char is not completely ruled out in the PYSOLO project. A key innovation of the PYSOLO technology is that the pyrolysis process can be operated in two ways: It is run by CSP during sunny hours, while it is fuelled by burning pyrolysis gas and char when the (stored) CSP heat is not sufficient. The PYSOLO technology can also balance the electric grid: if necessary, the pyrolysis gas can be converted into electricity and fed into the grid. On the other hand, if cheap and surplus renewable energy is available from the electric grid, it can be converted into high-temperature heat energy to sustain the pyrolysis process. The PYSOLO process is thus a uniquely flexible system that can cope with many different conditions.